Being a quality control specialist means ensuring products meet top-notch standards. Your role involves carrying out meticulous inspections, analyzing data, and identifying areas for improvement.

From conducting quality audits to implementing corrective actions, your skills extend to organization and problem-solving. Crafting a resume may feel out of your comfort zone, but fear not. We know what we’re doing, and we’re here to help make things simple.

Explore our quality control resume examples and cover letter writing tips to ace this vital step in landing your ideal job.

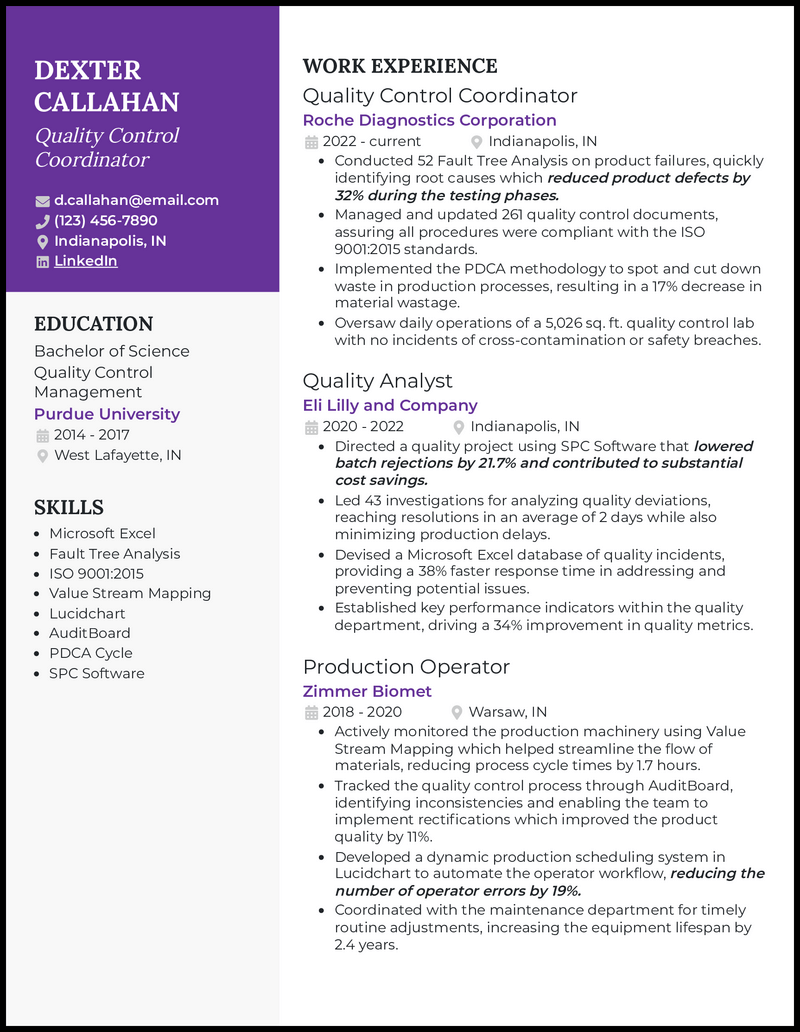

Why this resume works

- Your main job here is to ensure that a company’s quality control process is efficient and runs smoothly, hence list any past experience that depicts your ability to do so in your quality control resume.

- Enrich all bullet points with quantified metrics that clearly state how you’ve lowered operation errors, product rejections, and defects to show your employer that you’re all ready to take on the job!

Why this resume works

- As someone who’ll be working very closely with ensuring each product is meeting the required standards, your quality control inspector resume needs to have a versatile skill set of monitoring tools such as PC-DMIS, Keyence IM Series, and Fluke MET/CAL.

- Don’t just add them for the sake. Rather, describe how you’ve used each software to calibrate and measure products to ensure they comply with regulations needed by a company.

Why this resume works

- This is one instance where having a relatively longer career objective in your quality control manager resume isn’t going to hurt your chances. Take the opportunity to highlight exactly why you’re fit to be a manager whether through your education or past jobs.

- Don’t forget to add an essential skill such as ISO 9001:2015 standard for highlighting your enthusiasm and readiness to leverage your expertise and meet all current industry regulations in quality assurance.

Why this resume works

- Listing down any previous roles where you’ve directly dealt with assembling items in your quality control specialist resume will show a potential employer that you have an eye for detail.

- The only thing remaining now will be adding numbers that show you’ve used your attention for detail to make a difference such as resolving 78% of open quality issues within a month.

Why this resume works

- Take charge of your quality control technician resume by mentioning your education in this field. Even if it’s only a diploma in quality control, don’t sleep on it!

- Take inspiration from Ignacio and craft bullet points that showcase your ability to not just maintain high compliance rates with external audits but also use the 5 Whys technique for investigating the root cause of production delays and making improvements on it.

Related resume examples

Tailor Your Quality Control Resume to Suit Every Application

It’s time to show off your meticulous eye for detail and commitment to excellence. If you’re a pro at using inspection tools and statistical analysis or proficient in quality management systems, shout it from the resume rooftops.

Organize your technical skills in a clear way, emphasizing your expertise in the areas mentioned in the job description, such as statistical process control, Lean Six Sigma methodologies, and proficiency with quality assurance software.

Need some inspiration?

15 best quality control skills

- Inspection Techniques

- Statistical Analysis

- Quality Assurance

- Lean Six Sigma

- Precision Measurement

- Calibration Procedures

- Process Optimization

- Root Cause Analysis

- Managing Documentation

- Minitab

- Materials Testing

- NDT

- Microsoft Office

- Technical Reporting

- Multimeter Operation

Your quality control work experience bullet points

From implementing rigorous inspection procedures to fine-tuning quality assurance protocols, you ensure product quality and excellence. These end results are what you need to focus on in your work experience section.

Whether it’s enhancing inspection efficiency, reducing defects, or implementing process optimizations, these accomplishments showcase your impact. Drive the point home with metrics, illustrating the tangible results of your efforts.

Remember, your success directly influences the overall quality of the products, making your contribution indispensable—and this is what you need to prove to the hiring manager.

- Highlight your impact by quantifying the reduction in product defects after implementing new quality control measures.

- Express the percentage increase in the number of products inspected within a specific timeframe, demonstrating your ability to enhance throughput without compromising quality.

- Showcase your knack for streamlining processes by specifying the time reduction achieved through various optimizations.

- Incorporate customer satisfaction metrics to emphasize the downstream impact of your quality control efforts.

See what we mean?

- Administered supplier quality audits via Document Locator, lowering complaints on supplier-related defects by 26%

- Developed Gantt Charts for project timelines, ensuring on-time delivery of quality control projects and reducing delays by 16%

- Improved product testing protocols which led to a 14% reduction in defects across Lutron’s light control products

- Led the implementation of Zetec NDT solutions, shrinking inspection times for certain components by 1.7 hours

9 active verbs to start your quality control work experience bullet points

- Implemented

- Optimized

- Standardized

- Enhanced

- Collaborated

- Revitalized

- Developed

- Devised

- Instituted

3 Tips for Writing an Outstanding Entry-Level Quality Control Resume

- Demonstrate analytical skills

- If you have hobbies or interests related to analytical thinking or attention to detail, include them. Activities like puzzle-solving, data analysis in personal projects, or involvement in quality-focused clubs can show your inherent skills and dedication to precision.

- Highlight relevant coursework

- If your work experience is limited, shine a spotlight on your academic achievements instead. List coursework directly related to quality control, emphasizing subjects like statistical analysis, quality assurance methods, and materials testing.

- Show off your certifications

- Include any relevant certifications you’ve earned to emphasize your commitment. This includes the CQT or the Six Sigma Yellow Belt.

3 Tips for Writing an Experienced Quality Control Resume

- Quantify achievements with metrics

- Whether it’s the percentage improvement in defect reduction or the efficiency gains achieved in inspection processes, quantifiable data is essential. Metrics not only catch the eye of recruiters but also provide concrete evidence of your contributions to quality control.

- Utilize an ATS-friendly format

- To master applicant tracking systems (ATS), pick the right resume format. Use a clean, organized layout with relevant keywords strategically placed. Present your experience in quality control in the reverse chronological format for clarity.

- Tailor your skills section to the job description

- Customize your skills section based on the specific requirements outlined in the job description. Align your technical and soft skills with the key qualifications sought by employers to make sure your resume gets the proper attention.

It wouldn’t hurt! Customize it by mentioning the company and exact role in quality control to make it clear that you’re not sending out identical resumes to every job.

Always tailor your skills section to the job description, emphasizing both technical skills relevant to quality control. This includes relevant software, such as Fault Tree Analysis, and things like efficiency methodologies.

Focus on transferable skills that help you excel in quality control. This includes attention to detail, problem-solving, and data analysis.